Machinery Portal

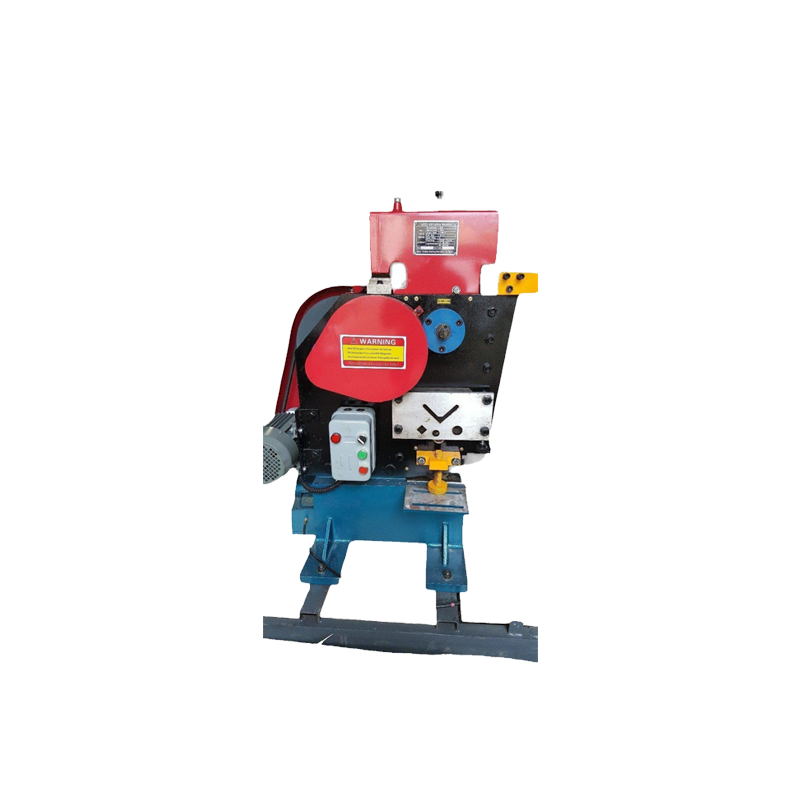

Iron Worker Machine in Wazirpur

Technical Intelligence

Usage/Application

Iron Worker Machine

Voltage

415 V

Motor Speed

2880 rpm

Power Source

Electric

Weight

400Kgs

Motor Power

5 HP

Model

GQ50-H

Max Bending Radius

21 mm

Frequency

50 Hz

Country of Origin

Made in India

Technical Variants

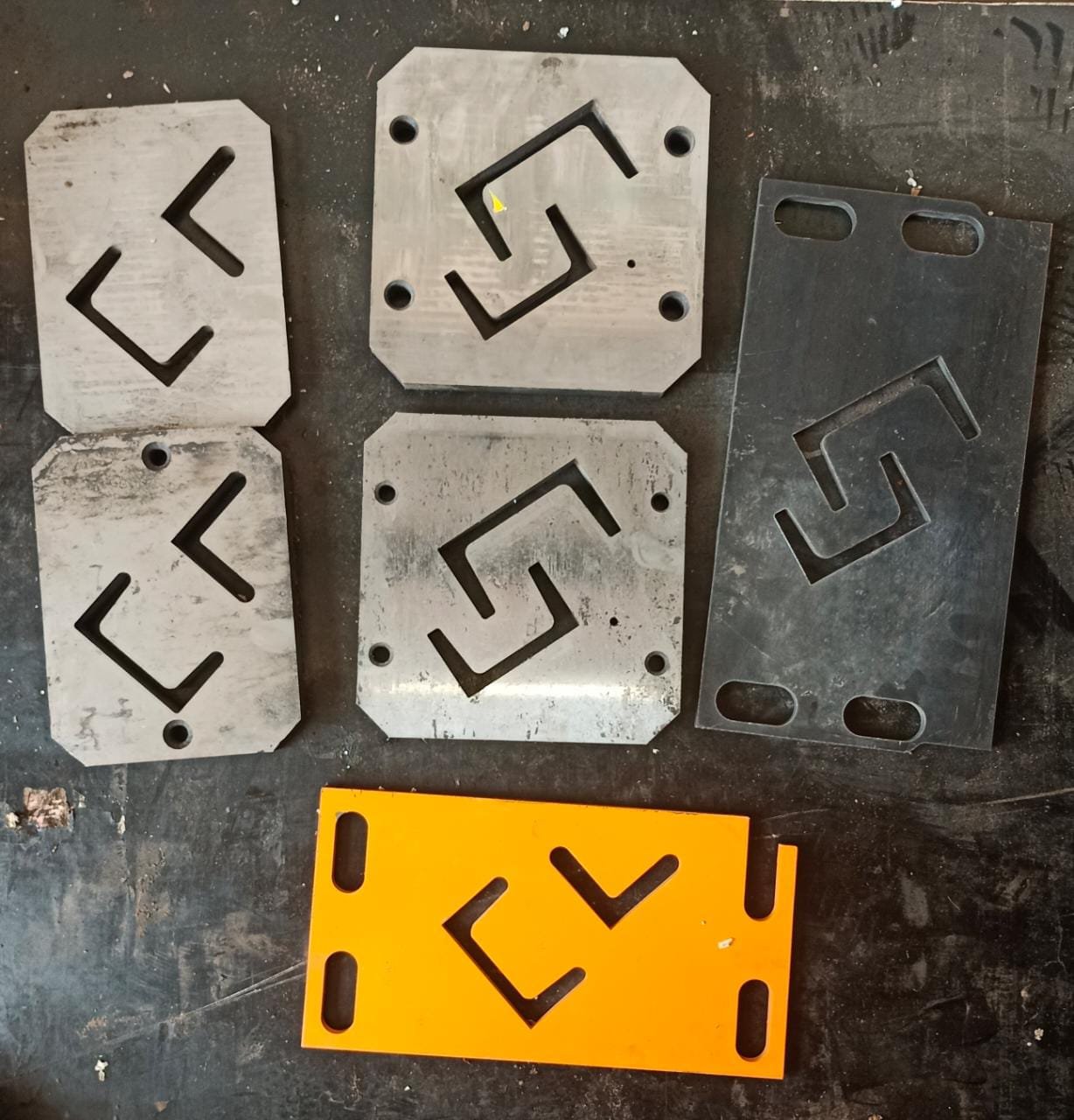

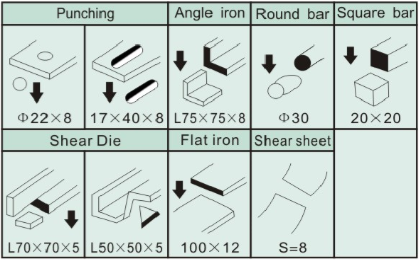

| Usage/Application | Punching & Shearing Machine |

| Automation Grade | Semi-Automatic |

| Power Source | Electric |

| Bar Dimensions | 32 mm (TMT Bar) |

| Brand | Topall |

| Motor Power | 5 HP |

| Model | GQ50-H |

| Max Bending Radius | 21 mm |

| Frequency | 50 Hz |

| Country of Origin | Made in India |