Machinery Portal

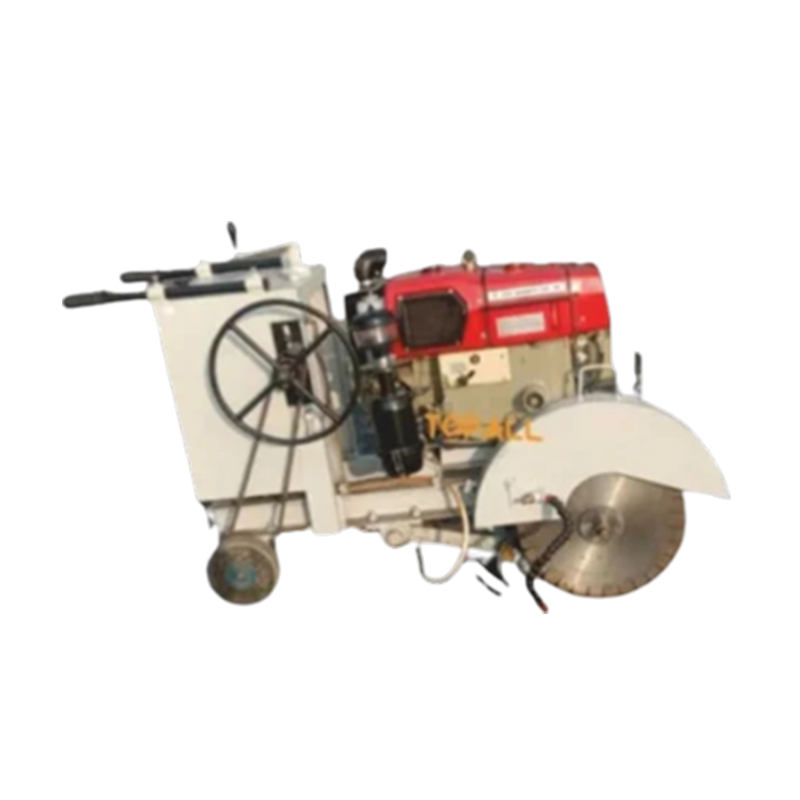

Groove Cutter

Technical Intelligence

Usage/Application

Groove Cutter

Driving Method

Manual Push

Engine Type

Honda GX270 Petrol

Operation Mass

90 Kg

Water Tank Capacity

35 L

Depth Adjustment

Handle Rotation

Engine

Air-cooled,4- cycle,single cylinder

Blade Size

12-20 inches

Model

CQF16

Country of Origin

Made in India

Technical Variants

| Usage/Application | Laser Levelling Machine |

| Rated Motor Power | 1200 Watt |

| Surface Recommendation | Granite, Marble |

| Drive Type | Gear Box Drive |

| Current Type | 220-240 V | 50 Hz |

| Motor Phase | Single Phase |

| Noise Level | Less than 70 dB |

| Weight | 741 kg |

| Country of Origin | Made in India |

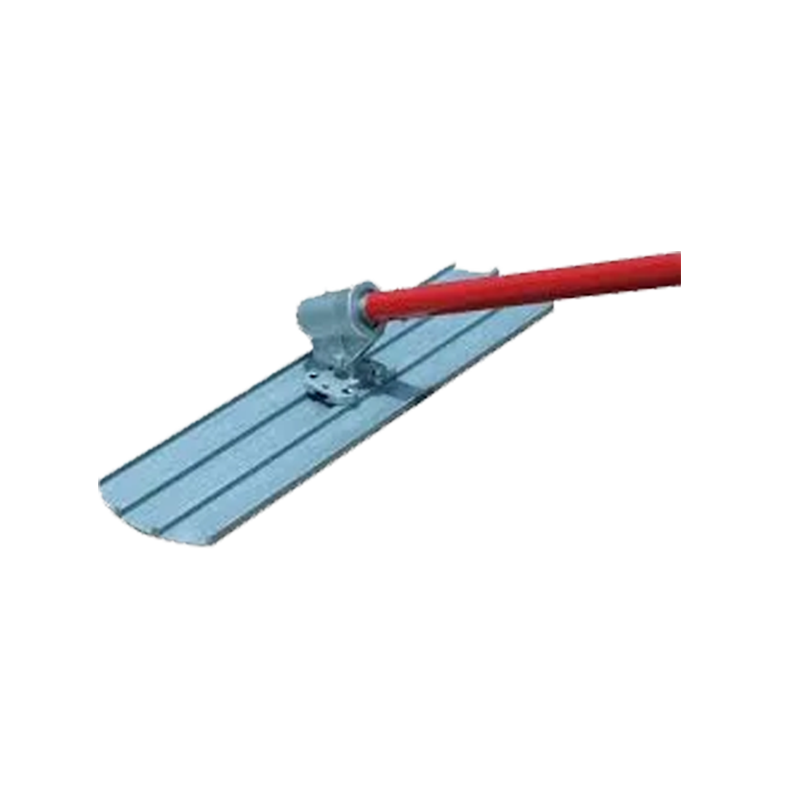

| Usage/Application | Bull Float |

| Blade Material | Magnesium |

| Width | 36 |

| Brand | Topall |

| Finishing | Smooth |

| Operating Mode | Manual |

| Length | 24 - 28 inch |

| Bracket Material | Cast Aluminum |

| Bracket Type | Worm Gear |

| Country of Origin | Made in India |

| Usage/Application | Bump Cutter |

| Handle Length | 1.8 m |

| Operation Mode | Manual |

| Brand | Topall |

| Blade Lenght | 3 m |

| Number of handles | 3 Pcs |

| package size | 3040 x 90 x 140 mm |

| Weight | 13 Kg |

| Screed Material | Aluminum |

| Country of Origin | Made in India |

| Model | CVS25C - CVS25E |

| Weight (Kgs) | 20 - 25 |

| Dimension (mm) | 2000 × 200 × 960 |

| Drive | Flexible Shaft , Shutter Motor |

| Power | Air Cooled, 4-Cycle, Gasoline , Three Phase Electrical |

| Type | Honda GX35, Imported |

| Max Output | 0.2 HP - 1.2 HP |

| Fuel Tank (Gal) | 0.65 (0.17) |

| Usage/Application | Ride on Trowel |

| Material | Power Trowel |

| Power | 34 Hp |

| Disc Thickness | 3 mm |

| Weight | 598 Kg |

| Size | 2540 * 1240 * 1485 (mm) |

| Round Disc Blade Diameter | 1200 mm |

| Quantity Of Blade | 10 blades |

| Engine Type | Kohler CH 940 |

| Country of Origin | Made in India |

| Usage/Application | Power Trowel |

| Working Diameter | 915 mm |

| Dimensions | 1820 x 945 x 980 mm |

| Engine Power | 5 HP |

| Model | CWD 40 |

| Oil Tank Capacity | 3.6 L |

| Pan Quantity | 1 Piece |

| Blade Quantity | 4 Pieces |

| Working Speed | 70-125 RPM |

| Country of Origin | Made in India |

| Model | QJM 600 |

| Working Diameter (mm) | 600 |

| Engine Type | Honda GX 160 |

| Max. Output (HP) | 5.5 |

| Weight (Kg) | 53 |

| Dimension (mm) | 1460 × 660 × 980 |

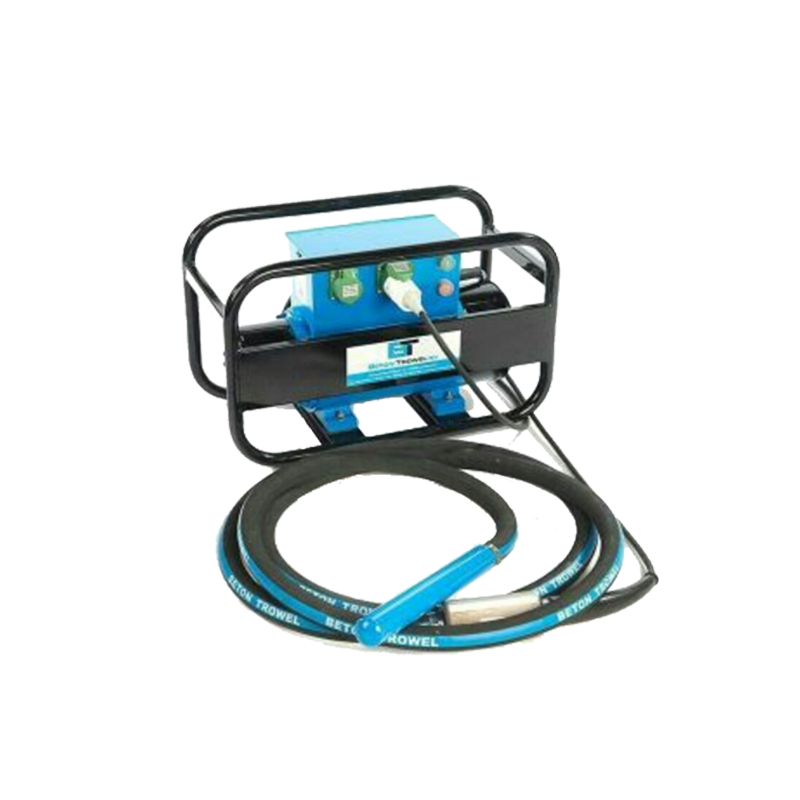

| Usage/Application | High Frequency Vibrators |

| Input Voltage | 115 |

| Power | 42v |

| Model Name/Number | HVU110 |

| Brand | Topall |

| Output Power | 2.3kw |

| Input Phase | Three Phase |

| Speed | 18000 |

| Phase | 3 |

| Country of Origin | Made in India |

| Usage/Application | Hardener Spreader |

| Automation Grade | Semi Automatic |

| Product Type | Hardner Material spreader |

| Brand | Topall |

| Roller Type | Semi Automatic |

| Capacity | 100 kg |

| Material | Stainless Steel |

| Fuel Tank Capacity | 12 |

| Minimum order quantity | 1 Number |

| Country of Origin | Made in India |

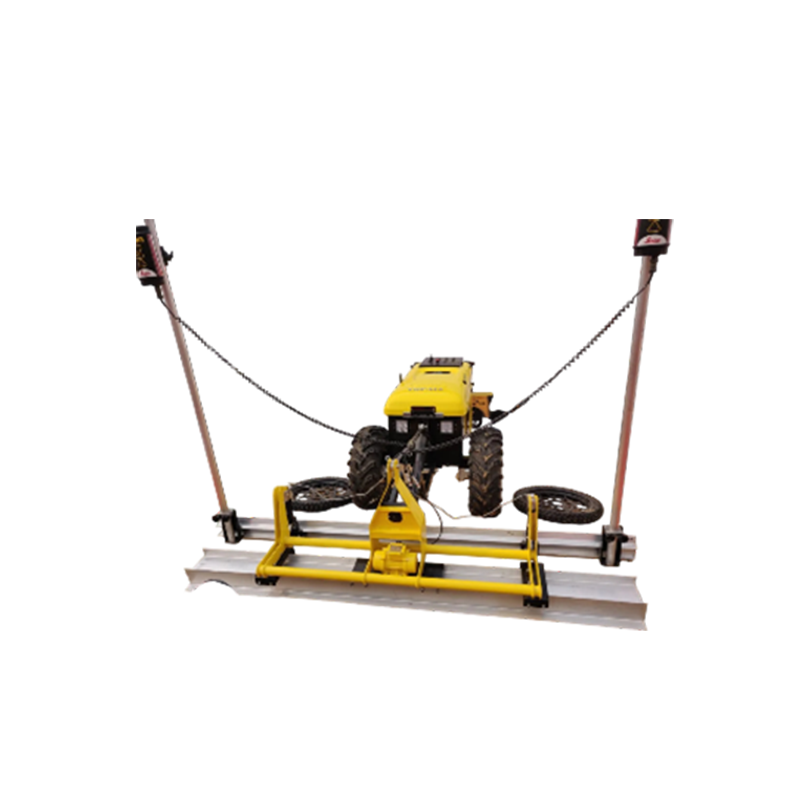

| Usage/Application | Walk Behind Laser Screed Machines |

| Rated Motor Power | 1200 Watt |

| Surface Recommendation | Granite, Marble |

| Drive Type | Gear Box Drive |

| Current Type | 220-240 V | 50 Hz |

| Motor Phase | Single Phase |

| Noise Level | Less than 70 dB |

| Weight | 741 kg |

| Country of Origin | Made in India |

| Model | GT 250 |

| Weight (KG) | 160 |

| Dimension (MM) | 1050x500x100 |

| Working Width (MM) | 5~8 |

| Voltage | 451V, 50/60 Hz, 3 Phase |

| Cutter Quantity (PCS) | 108 |

| Model | GT-630 |

| Weight (KG) | 300 |

| Voltage (V) | 380 |

| Working Width (MM) | 600 |

| Inverter (KW) | 7.5 |

| Motor Power (KW) | 7.5 |

| Mill Speed (RPM) | 0-1800 |

| Model | GT330 / GT400 |

| Motor Power | 4KW / 3KW |

| Inverter Speed | 1450 r/min / 900 r/min |

| Power Supply | 380V |

| Weight | 145 KG / 75 KG |

| Vacuum Motor Power | 750W / - |

| Dimension (L×W×H) | 1100x460x980 |

| Model | CQF 20 / CQF 28 / CQF 40 |

| Blade Size | 12-20 in / 16-28 in / 20-40 in |

| Cutting Depth | 160 mm / 225 mm / 400 mm |

| Engine Type | Honda / Greaves / Electric Motor / VST Shakti Engine |

| Power (HP) | 5/9 HP / 9/13 HP / 15/20/25 HP |

| Water Tank | 35 Ltr / 30 Ltr / 40 Ltr |

| Depth Adjustment | Handle Rotation |

| Weight | 95 kg / 180 kg / 280 kg |

| Model | QUM-80 |

| Blade Quantity | 8 Pcs |

| Pan Quantity | 2 Pcs |

| Working Speed | 120-140 RPM |

| Working Diameter | 1900x915 mm |

| Engine | Honda GX690 24HP |

| Max Speed | 3600 RPM |

| Fuel Tank Capacity | 12 Ltr |

| Disc Diameter | 940 mm |

| Spare Parts | Combination Blade |

| Pan | Made of 3mm Thickness, Manganese Steel (2 Pcs) |

| Dimension (mm) | 1980x996x1320 |

| Weight (Kg) | 310 |

| Model | CWT 40 / CWT 40L / DMR 900 |

| Working Diameter (mm) | 900 / 915 |

| Engine Type | Honda GX 160 |

| Max. Output (HP) | 5.5 |

| Weight (Kg) | 100 / 120 |

| Dimension (mm) | 1280x945x980 |

| Model | BT 900 - 2PF H24 |

| Type | BT Low Riders |

| Engine Type | Honda GX 690, 24HP |

| Blade Rotation Speed | 0-140 RPM |

| Float Pans | Yes |

| Blades | 8 Pcs |

| Dimensions (mm) | 1940x990x1040 |

| Weight Dry (kg) | 275 |

| Model | BT-60H |

| Working Diameter (mm) | 600 |

| Engine Type | Honda GX 160 |

| Max. Output (HP) | 5.5 |

| Weight (Kg) | 53 |

| Dimension (mm) | 1460x660x980 |

| Model | BT-90H |

| Working Diameter (mm) | 900 |

| Engine Type | Honda GX 160 |

| Max. Output (HP) | 5.5 |

| Weight (Kg) | 120 |

| Dimension (mm) | 1280 × 945 × 980 |

| Model | BTFC/45/4, BTFC200/18/2 |

| Capacity | 1.8KVA, 4.5KVA |

| Input (Phase/Hz/V/A) | 3Ph/ 50 / 380 / 2.8, 3Ph/ 50 / 380 / 8.3 |

| Output (Phase/Hz/V/A) | 3Ph/ 200 / 48 / 22, 3Ph/ 200 / 48 / 54 |

| Weight | 37 Kgs, 78 Kgs |

| Units Driving | 2 Needles, 4 Needles |

| Model | HVU110, HVU220 |

| Voltage | 115V, 230V |

| Power (Kw) | 2.3 |

| Motor Speed | 18000 |

| Weight | 5.5Kg |

| Model | HDV38/2, HDV38/4 |

| Dia | 38mm |

| Length | 2m, 4m |

| Weight | 6.26kg, 8.86kg |

| Frequency | 16200 |

| Amplitude | 1.54 |

| Model | LS-325 |

| Generator | Honda EC2500 x (2.6Kw, Single Cylinder Four Stroke Generator Set) |

| Package | Box 1:2700*1050*1350mm Box2:2900*750*320 |

| Laser Generator | LEICA (Switzerland) (635nm visible laser, self-leveling, level error<+1.5mm/30m, effective lanuch distance 300m) |

| Laser Receiver | LEICA (Switzerland) (effective receiving distance 300m, accuracy of dead zone<+2.5mm) |

| Control System | Ac Servo System |

| Driving System | Phase (Italian) (steeples adujustment, turning faster than 1:2:5) |

| Airframe Adjustment | Level Sensor automatic adjusting system |

| Slope Working | Single Phase Slope Automatic Adjustment |

| Wheel Tyre | 733nm ATV (1.8-2.2BAR)/3.0-21 narrow tyre (1.6-2. 1 BAR) |

| Virating System | Eccentric Vibration Moror, 300Hz |

| Centrifugal Force | 100 Kgs |

| Vibrating System | Aluminium Alloy |

| Scraper Blade | Aluminium Alloy |

| Scraper Adjustment | Computer Control, Automatic Adjustment |

| Working Length | 2.6M |

| Reverse Speed | 2.5Km/H |

| Min. Ground Clearance | 355mm |

| Ground Flatness | <+7mm/100m |

| Max Working Radius | <200mm |

| Working | 200m2/h--350m2/h |

| Dimension (L*W*H) | 2748*2900*2044 |

| Weight | 230Kgs |

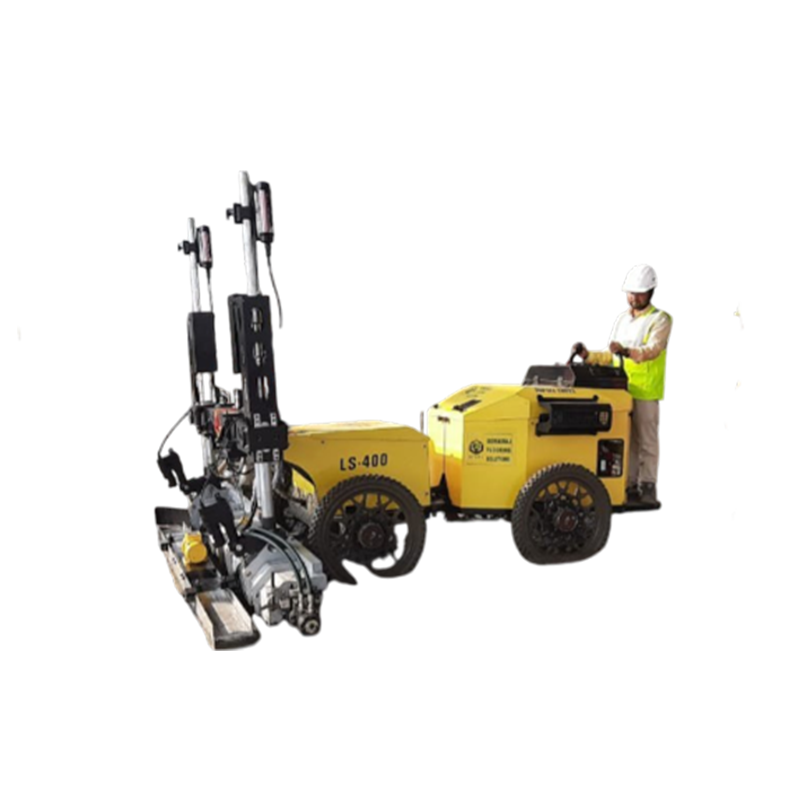

| Model | LS-400 |

| Engine Model | Kholer Ch620 |

| Engine Type | Petrol, V-cylinder engine, air cooling |

| Engine Power (Kw) | 14.2 |

| Lubrication Oil (L) | 2 |

| Fuel Tank Capacity (L) | 35 |

| Type of Leveling | Independent suspension, center rotation |

| Paving Width (mm) | 2500 |

| Paving Way | scraper blade paving |

| Paving Thickness (mm) | 30-200 |

| Boom Motor | High torque hydraulic motor |

| Vibrating System Control | Vibrating Motor |

| Exciting force (kg) | 100 |

| Vibrational Frequency (hz) | 50 |

| Laser System Control Type | Laser Scanning + High Sensitivity DC Push road |

| Laser System Control Effect | Flat surface, slope Floor |

| Driving System | Hydraulic driving tyre |

| Wheel | Heavy-duty tyre |

| Walking Speed (km/h) | 0-2.5 |

| Forword/backward | Switch Control, Stepless speed |

| Turing | Switch Control |

| Dimension (mm) | 3155x3175x1910 |

| Weight | 741 |

| Model Name | Concrete Paver XP-900 |

| Paving Width | 3.5 to 9 Meters |

| Engine Power | 110 HP Diesel Engine |

| Paving Speed | 0–5 M/min |

| Working Efficiency | 400 m²/hour |

| Vibration System | High-Frequency Vibration Motor |

| Leveling Accuracy | ±2 mm |

| Control Panel | Digital Smart Control System |

| Fuel Tank Capacity | 80 Litres |

| Weight | 2600 Kg |

| Model Name | BT Edger Trowel |

| Trowel Diameter | 24 Inches |

| Engine Type | Honda GX160 / Equivalent |

| Power | 5.5 HP |

| Trowel Speed | 60–125 RPM |

| Blade Size | 9 x 4 inches |

| Weight | 70 Kg (Approx.) |

| Operating Handle | Foldable with Adjustable Height |

| Application | Edge Finishing of Concrete Floors |

| Country of Origin | India |

| Model | BT Floater 100 |

| Engine Type | Petrol Honda GX160 |

| Power | 5.5 HP |

| Working Width | 1000 mm |

| Blade Size | 350 mm x 150 mm |

| Blade Quantity | 4 |

| Fuel Tank Capacity | 3.6 L |

| Weight | 90 Kg |

| Speed | 70–130 RPM |

| Application | Surface Finishing & Smoothing |

| Model | GX65 Grinding Machine |

| Grinding Wheel Size | 300 mm |

| Power Supply | 3 Phase, 415V |

| Motor Capacity | 5 HP |

| Table Size | 600 x 300 mm |

| Surface Finish | ≤ 2 Micron |

| Max Workload | 200 kg |

| Cooling System | Integrated |

| Material Suitability | Steel, Cast Iron, Alloys |

| Brand | Topall Impex |

| Model | IVC-F33L |

| Type | Industrial Vacuum Cleaner |

| Power | 3300 Watts |

| Voltage | 220V / 50Hz |

| Tank Capacity | 60 Liters |

| Material | Stainless Steel |

| Filter Type | HEPA + Cloth Filter |

| Noise Level | ≤ 78 dB |

| Mobility | 4-Wheel Portable |

| Brand | Topall Impex |

| Model | Sino S300 |

| Type | Surface Grinding Machine |

| Grinding Area | 600 x 300 mm |

| Motor Power | 5 HP |

| Table Load Capacity | 250 kg |

| Voltage | 415V AC |

| Wheel Speed | 2800 RPM |

| Cooling System | Integrated Coolant Tank |

| Operation | Semi-Automatic |

| Brand | Topall Impex |

| Model | HTG-820C |

| Type | Autopilot Planetary Grinder |

| Working Width | 820 mm |

| Grinding Disc | 3 x 300 mm |

| Voltage | 380V / 3 Phase |

| Motor Power | 15 KW |

| Rotation Speed | 350–1950 rpm |

| Weight | 585 kg |

| Water Tank Capacity | 20 Liters |

| Application | Concrete, Stone, Epoxy Floors |

| Model Name | IVC-45L |

| Working Width | 820 mm |

| Grinding Disc | 4 Discs / 12 Heads |

| Motor Power | 15 HP (11 kW) |

| Voltage | 380V-440V 3 Phase |

| Speed Range | 300–1800 RPM |

| Water Tank Capacity | 20 Litres |

| Net Weight | 580 kg |

| Transmission | Gear Drive + Belt Drive |

| Application | Concrete Floor Grinding & Polishing |

| Model | 995 LE |

| Grinding Width | 800 mm |

| Power Output | 15 HP |

| Voltage | 380V, 3-Phase |

| Grinding Disc Speed | 300–1800 RPM |

| Weight | 600 Kg |

| Grinding Pressure | Adjustable |

| Dust Collection Port | Yes |

| Operation Mode | Manual & Auto |

| Application Area | Concrete, Stone, Epoxy Removal |

| Model | GX688-4A |

| Power Output | 15 HP |

| Voltage | 380V |

| Working Width | 680 mm |

| Grinding Heads | 4 |

| Speed | 300–1800 RPM |

| Water Tank Capacity | 30 Liters |

| Machine Weight | 410 Kg |

| Dust Extraction Port | Yes |

| Application Area | Industrial/Commercial Floors |

| Model | GT250 |

| Motor Power | 3 HP |

| Voltage | 220V / 50Hz |

| Grinding Width | 250 mm |

| Disc Speed | 1400 RPM |

| Weight | 65 kg |

| Dust Port | Yes |

| Application Area | Concrete, Marble, Epoxy |

| Frame Material | Heavy-duty Steel |

| Operation | Manual Push Type |

| Model | GT630 |

| Grinding Width | 630 mm |

| Motor Power | 10 HP |

| Voltage | 380V / 3 Phase |

| Speed Range | 300–1800 RPM |

| Working Pressure | Adjustable |

| Tool Holder | 3 Planetary Plates |

| Weight | 340 kg |

| Application | Floor Grinding & Polishing |

| Dust Port | Yes (vacuum compatible) |

| Model | GT330 |

| Motor Power | 4 kW / 5.5 HP |

| Voltage | 380V / 3 Phase |

| Grinding Width | 330 mm |

| Disc Speed | 300–1200 RPM |

| Number of Discs | 3 |

| Weight | 150 kg |

| Water Tank Capacity | 30 L |

| Application | Floor Grinding & Polishing |

| Usage | Industrial / Commercial |

| Model | HTG-460 |

| Grinding Width | 460 mm |

| Motor Power | 4 kW |

| Voltage | 220V / 380V |

| Phase | Single / Three Phase |

| Rotation Speed | 300–1600 RPM |

| Tool Holder Type | Magnetic Plate |

| Water Tank Capacity | 20 Liters |

| Machine Weight | 150 kg |

| Application | Concrete, Terrazzo, Epoxy Floor |

| Model | 580-2 Grinding Machine |

| Power | 7.5 HP |

| Voltage | 380V |

| Working Width | 580 mm |

| Grinding Heads | Dual |

| Weight | 180 Kg |

| Rotation Speed | 300–1800 rpm |

| Water Tank | 30 Liters |

| Application Area | Concrete, Epoxy Removal |

| Usage Type | Industrial / Commercial Floors |