Machinery Portal

Mesh Bender

Technical Intelligence

Usage/Application

Mesh Bender

Automation Grade

Semi-Automatic

Model Name/Number

GW-42J

Power Source

Electric

Bar Dimensions

32 mm (TMT Bar)

Brand

Topall

Max Bending Angle

180 Degree

Max Bending Radius

21 mm

Frequency

50 Hz

Country of Origin

Made in India

Technical Variants

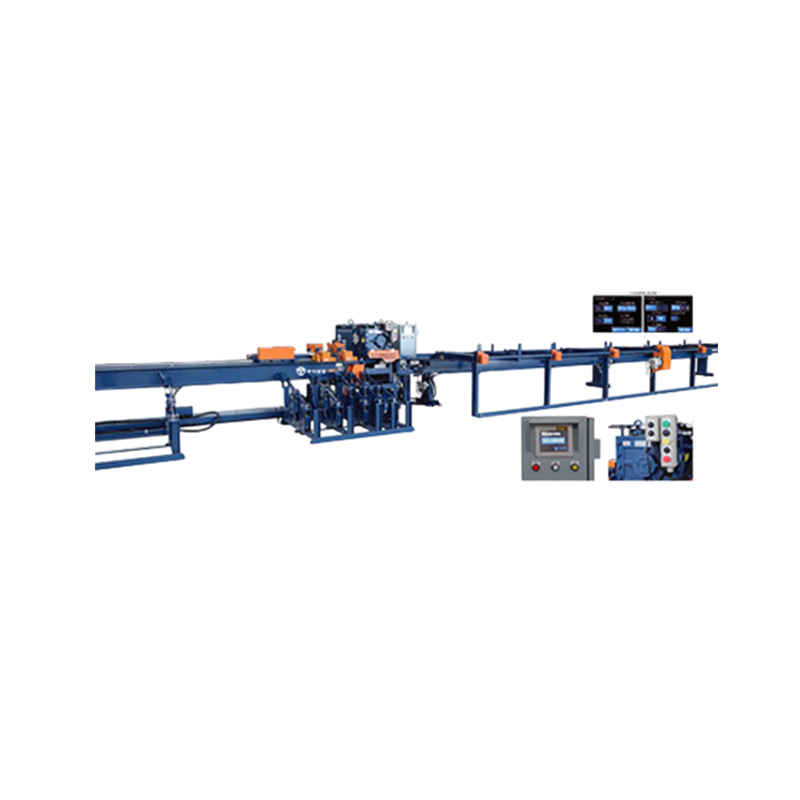

| Usage/Application | Automatic Shear Line |

| Max Bending Radius | 0-50 mm |

| Model Name/Number | GW20 |

| Power Source | Electric |

| Voltage | 415 V |

| Weight In Kg | 90 - 95 |

| Bending Range | 4 - 16 mm |

| Model | GW 20 |

| Minimum order quantity | 1 Unit |

| Country of Origin | Made in India |

| Usage/Application | Automatic Bender Line |

| Max Bending Radius | 0-50 mm |

| Model Name/Number | GW20 |

| Power Source | Electric |

| Voltage | 415 V |

| Weight In Kg | 90 - 95 |

| Bending Range | 4 - 16 mm |

| Model | GW 20 |

| Minimum order quantity | 1 Unit |

| Country of Origin | Made in India |

| Usage/Application | Automatic Stirrup Machine |

| Max Bending Radius | 0-50 mm |

| Model Name/Number | GW20 |

| Capacity | 10mm |

| Bar Dimensions | 32 mm (TMT Bar) |

| Brand | Topall |

| Max Bending Angle | 180 Degree |

| Max Bending Radius | 21 mm |

| Frequency | 50 Hz |

| Country of Origin | Made in India |