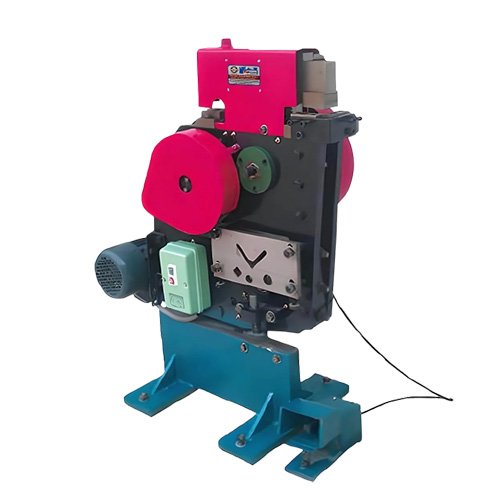

As the Director of Topall Impex, I am both humbled and excited to lead this journey of innovation and excellence in flooring and construction machinery. Our mission is not just to meet the industry standards but to set them, delivering reliable, high-quality solutions that empower construction professionals to achieve outstanding results in every project. In today’s rapidly advancing world, our industry demands a blend of tradition and innovation. At Topall Impex, we are committed to investing in cutting-edge technology, developing sustainable practices, and cultivating a team of skilled professionals who share our vision of exceptional service and craftsmanship. Our customers are at the heart of everything we do. We are dedicated to understanding and fulfilling your needs, ensuring that every product we deliver brings added value to your projects. This approach has been a cornerstone of our success, and we are grateful for the trust you place in us. A stirrup bending machine is a specific type of rebar machine designed to bend rebars into stirrups closed-loop shapes essential in reinforcing concrete. Stirrup benders automate the bending process to create precise, uniform shapes, improving both speed and accuracy in creating these structural elements. Both machines play crucial roles in construction, especially in creating structural reinforcements for beams, columns, and other load-bearing elements in concrete structures.